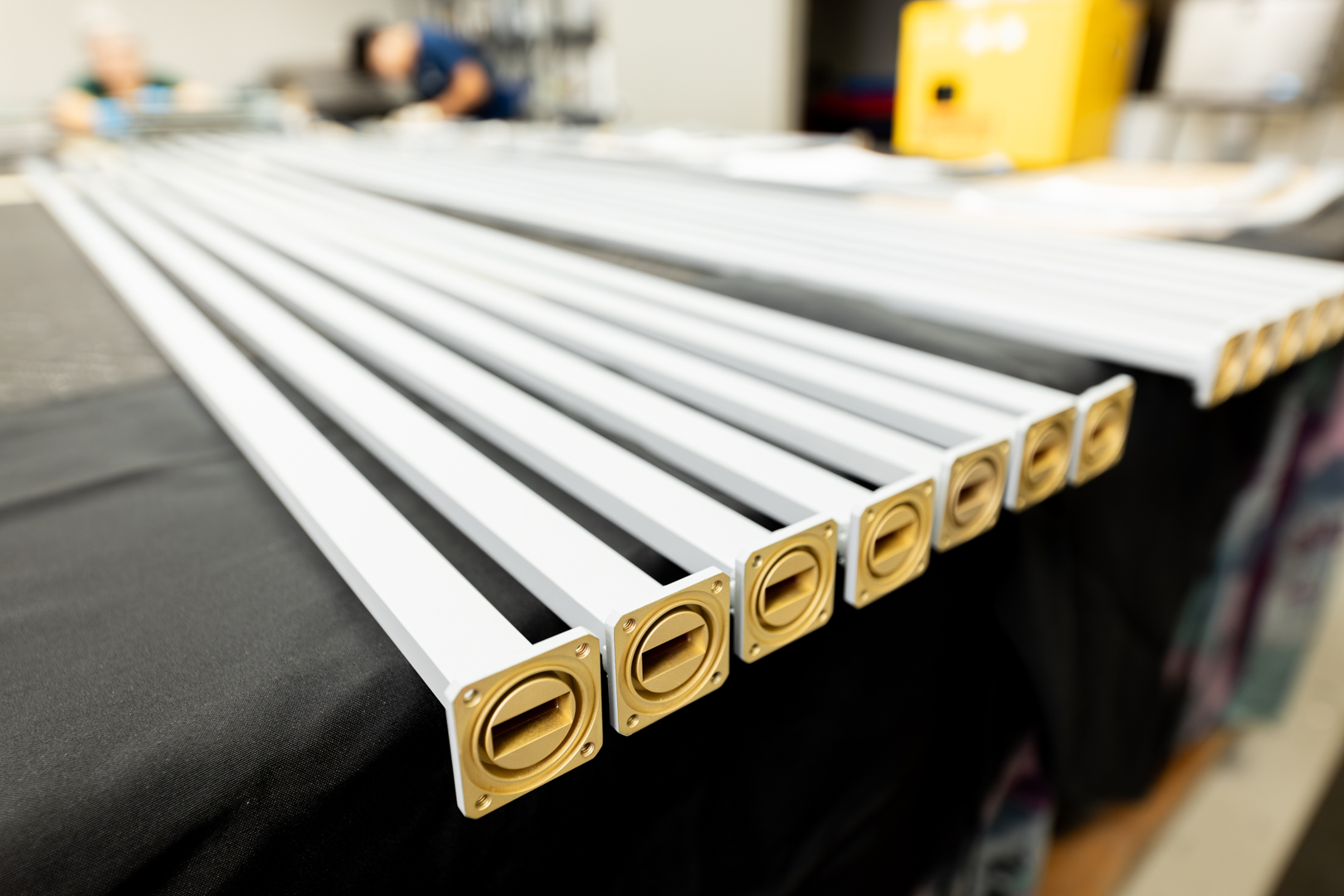

Manufacturing waveguides for high-frequency applications is challenging due to the need for precise dimensional control and smooth inner surfaces to minimize losses, especially at higher frequencies. Additionally, complex shapes or integrated systems may require advanced manufacturing techniques such as 3D printing or microfabrication. Joining and sealing waveguide sections while maintaining electrical continuity can be difficult, particularly for applications requiring high vacuum or pressurized environments.